Wastewater System: Submerged Filter Extended Aeration (SFEA)

Waterworks’ packaged SFEA treatment plants meet the needs of small businesses, municipalities, RV parks, hotels, resorts or other facilities where the total volume of waste is small (less than 38 m3 per day).

SFEA offers small sewage and wastewater situations low operating cost and discharge requirements.

The pre-engineered systems are engineered for stand alone sewage treatment performance or to reduce industrial waste surcharges.

SFEA removes 95% of the influent BOD and TSS, and 90% or more of the oil and grease load. When combined with optional tertiary treatment devices, 99% removal of BOD can be accomplished.

Chlorine or UV disinfection can be added to allow water reuse or discharge to sensitive environments.

Advantages of the SFEA systems:

- Small plant footprint

- Skid-mounted for easy transportation and installation

- Low maintenance and operations requirements

- Low capital and operating costs

- Stable during shock and stress loading

- Excellent treatment performance with low sludge production

Plant layout optional equipment: sludge digester, sludge press, chlorine contact tank, DAF, sand filtration, carbon filtration, and metals filters will enhance the SFEA ultimate water quality.

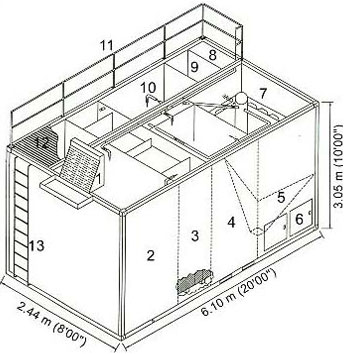

SFEA 38 m3/day Package

1-Stainless Steel Screen 2-Equalization Tank 3-Submerged Filter

4-Sludge Tank 5-Clarifier 6-Storage 7-Outlet Weirs

8-Electrical Controls 9-Chlorine Contact Tank 10-Extended Aeration Tank

11-Safety Rail 12-Walkway Grating 13-Access Ladder

The SFEA process combines submerged fixed film and extended aeration (EA) biological treatment strategies to effectively remedy up to 38 m3/day of high-strength wastewater in a compact, highly efficient unit.

Wastewater is first mechanically screened to remove primary solids, then collected in an aerated equalizing tank to smooth flow fluctuations. Aeration stops septic conditions from producing noxious odors, making the SFEA completely suitable for indoor operation or use near residential areas.

From the equalization tank, waste is pumped to the submerged aerated filter. The SFEA’s specialty filter media enhances hydraulic performance and provides a huge surface area for biological growth while oxygen (provided by submerged fine bubble diffusers) keeps the bacteria operating aerobically. The media’s high void volumes allow for virtually unhindered wastewater flow while eliminating clogging risks that are present in other filters. Submerged filter technology allows microorganisms to attach to the media and grow into dense layers of biofilm. As wastewater passes over the biofilm dissolved wastes and suspended solids are absorbed and decomposed. Layers of organisms grow and periodically fall off, passing into the next treatment stage, thus the filter never becomes blocked.

The submerged filter removes approximately 70% of the inlet waste products while the extended aeration compartment acts to remove the remaining organic wastes.

Fine pore diffusers ensure good oxygen transfer and mixing for the suspended growth process to proceed. Solids that enter from the filter, or new bacteria produced in the extended aeration process are continually mixed and recycled to maintain an active biomass.

The extended aeration effluent contains biological solids that are separated out in the clarifier and either returned to the process or removed for final disposal. The end product is clear and clean water.