Wastewater System: Trickling Filter Extended Aeration (TFEA) System

Waterworks’ Trickling Filter Extended Aeration (TFEA) system uses combined attached and suspended biological growth systems to

remove over 90% of soluble organics (BOD and COD) and suspended solids. The TFEA is suitable for treating both municipal sewage for

stand alone performance and tough industrial wastewaters for surcharge reduction.

In existing applications Waterworks’ TFEA has removed up to 95% of the influent BOD and TSS strength, and 90% or greater removal of oils and grease. When combined with optional tertiary treatment devices up to 99% removal of BOD can be attained.

Options include:

- Sludge digesters

- Sludge presses

- Ozone

- UV disinfection

- Chlorine disinfection

- Dissolved air filtration

- Sand filtration

- Carbon filtration

- Metal filters

The advantages of TFEA:

- Small plant footprint

- From 38 to 8,000 m3/day capacities in pre-packaged sizes

- Low maintenance and operations requirements

- Low capital and operating costs

- Stable during shock and stress loading

- Excellent treatment performance with low sludge production

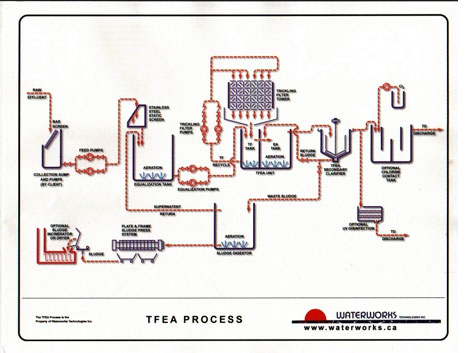

The TFEA process combines trickling film and extended aeration biological treatment strategies to rapidly consume high strength wastewaters in a compact, highly efficient unit. The TFEA packages are suitable for medium to large scale industrial and municipal processes.

Wastewater is screened and collected in an aerated equalizing tank to smooth flow fluctuations. Aeration stops septic conditions from producing noxious odors, making the TFEA completely suitable for indoor operation or use near residential areas. Waste is then pumped to the top of the filter and allowed to trickle over the packing media where bacterial growth removes waste products. The TFEA’s high porosity media prevents blockages, maintains hydraulic performance and provides a significantly larger surface area for biological growth.

Effluent is collected and recycled through the filter again to improve pollutant removal.The filter is sized to meet the needs of each application though even very large filters use a minimum amount of space. They can be stacked where height is no constraint or even completely assembled within existing structures. Expansion is easily accomplished should the need arise. The trickling filter removes more than two-thirds of the influent waste strength.

The extended aeration portion of the secondary treatment system is a polishing stage required to remove the remaining organic wastes. Fine pore diffusers ensure good oxygen transfer and mixing for the suspended growth process to proceed. Solids that enter from the filter or new bacteria produced in the extended aeration process are continually mixed and recycled to maintain an active biomass.The effluent from the extended aeration stage contains biological solids that are separated in the clarifier and either returned to the process or removed for storage. The end product is clear water. Chlorine or UV disinfection can be added to allow water reuse or discharge to sensitive environments.

Clients

Waterworks/Alpac TFEA systems have been installed for a large number of industrial and municipal clients. Some categories include:

- FOOD AND BEVERAGE INDUSTRY

- TOXIC CHEMICALS/ELECTRONICS INDUSTRY

- LATEX MANUFACTURING

- BREWERIES AND DISTILLERIES

- WASTEWATER TREATMENT FOR HOTELS, CAMP SITES

- TOBACCO PROCESSING

- MUNICIPAL SEWAGE

Kerns, Calistoga, Anubhav Agrotech, AM-CAN Beverages (Formerly Pokka Beverages), Pepsi/7-Up, Abita Brewing Company, etc.

PDS Rail Car Facility, EPA Superfund Sites, Acqutek Electronics, etc.

Rusch (Malaysia), Rusch (India), Bard, Mapa, Ansell etc.

North Malaya Chemical, etc.

White House, , Kamunting., etc.

R.J.Reynold, Malaysia, R.J. Reynolds, Russia White House, Kamunting., etc.

Silver Star Mountain Resort