Wastewater System: MBR Systems

Waterworks’ Membrane Bioreactor (MBR) systems applies the best technology and installations around the world to a variety of locations. Waterworks can supply pre-packaged systems or systems that meet with specific client needs. Designs can be “hollow fiber” based or “sheet” based membrane type. Also it can be provided as a skid mounted or containerized units.

Process Highlights

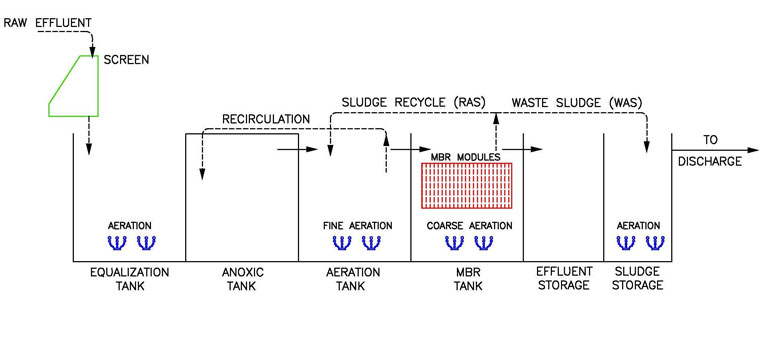

- Screening – Membrane bioreactor system requires screening down to 3 mm. The 3 mm screen can be static or rotating.

- Aeration Requirements – MBR units will require constant aeration, which is provided by supplying air to the MBR Units.

This air contributes to the aeration required for biological treatment. A high rate scour is required periodically for the

operation and also to prolong the lifetime of the membranes. - Operating MLSS – The MBR system allows operation at a MLSS concentration ranging from 12,000 to 18,000 mg/l in the MBR tanks.

Operation at this

elevated level results in smaller sludge volumes to be treated (or transported off site) relative to conventional treatment systems.

Advantages of MBR Systems

The advantages of MBR include:

Secondary clarifiers and tertiary filtration processes are eliminated, thereby reducing plant footprint. In certain instances, footprint can be further reduced because other process units such as digesters or UV disinfection can also be eliminated or minimized.

Unlike secondary clarifiers, the quality of solids separation is not dependent on the mixed liquor suspended solids concentration

or characteristics. Since elevated mixed liquor concentrations are possible, the aeration basin volume can be reduced, further

reducing the plant footprint operation and also to prolong the lifetime of the membranes.

Produces a MF/UF quality effluent suitable for reuse applications or as a high quality feed water source for reverse osmosis treatment. Indicative output quality of MF/UF systems include SS 1mg/L, turbidity 0.2 NTU and up to 4 log removal of virus (depending on the membrane nominal pore size).

In addition, MF/UF provides a barrier to certain chlorine resistant pathogens such as Cryptosporidium and Giardia.

The small footprint can be a feature used to address issues of visual amenity, noise and odors.

Some of the main influences for the increasing interest in MBR technology include:

- More stringent legislations for both sewage treatment plant and industrial effluent discharge

- Water scarcity

- Increasing interest in wastewater recycling

- Improvements in MBR technology

- Reducing development and land acquisition costs

Potential applications of MBR systems include:

- Increasing existing plant capacity

- Reverse osmosis feed pre-treatment

- Direct reuse

- Aquifer recharge

- Wastewater reclamation

- Nitrogen removal

- Phosphate removal